GLASS Laboratory: Gateway Laboratory of Amorphous and Structured Solids and Melts

Download here the brochure.

Established in 2023 in Rome with funding from the European Research Council (ERC) Consolidator Grant NANOVOLC, the GLASS Laboratory at the National Research Council of Italy (CNR), Institute of Science, Technology and Sustainability for Ceramics (ISSMC) is a pioneering research center dedicated to advancing the fundamental and applied understanding of amorphous and structured solids and melts. Our mission is to uncover the complex physicochemical processes that govern material behavior—ranging from volcanic eruptions to the development of advanced industrial materials such as glasses, ceramics, and high-performance melts.

Our mission

At GLASS, we pursue a dual mission:

- Basic research: We aim to unravel the physicochemical processes that underpin volcanic activity, providing insights into natural phenomena like eruptions, magma dynamics, and silicate melt behavior.

- Applied research: We translate our findings into practical applications for industrial partners, leveraging our expertise to develop next-generation materials with optimized properties for manufacturing, sustainability, and extreme environments.

Our laboratory serves as a bridge between cutting-edge academic research and industrial innovation, making it a vital partner for glass and glass-ceramics companies.

Research focus areas

- Volcanology and high-temperature high-pressure processes

Our foundational research centers on understanding the physicochemical behavior of silicate melts, magmas, and glasses, with a particular focus on volcanic processes. By exploring how these materials evolve under extreme conditions, we uncover the mechanisms that drive volcanic eruptions and other geophysical phenomena. These insights are not only critical for geoscience but also offer analogs for understanding and optimizing industrial melts and glass-forming processes. - Advanced materials design

We study the structure-property relationships of amorphous and structured solids to design and optimize materials for industrial applications. Our research informs the development of high-performance glasses and ceramics with enhanced durability, mechanical strength, and thermal stability, tailored to meet the needs of industries like optics, electronics, and construction. - Sustainability and circular economy

GLASS is at the forefront of sustainable materials research. We explore the reuse of natural raw materials and industrial by-products to create high-value materials for modern applications, helping industries align with circular economy principles. Our work aims to reduce waste, lower energy consumption, and promote eco-friendly production processes. - Extreme condition testing and material performance

With extensive capabilities to simulate extreme temperature and pressure environments, GLASS provides insights into how materials behave under demanding conditions. Whether it is replicating volcanic conditions or industrial manufacturing processes, our research helps develop materials that perform optimally in high-stress environments.

GLASS equipment

Our laboratory is equipped with standard tools for sample preparation, including high-temperature processes under various atmospheres, as well as advanced instrumentation that enables us to conduct both basic and applied research with high precision. This ensures detailed insights into the behavior and properties of various materials. For a full list of our equipment, please visit the ISSMC equipment page. Below is a list of the latest GLASS laboratory apparatus.

- Simultaneous Thermal Analysis (STA, TGA-DSC) with Evolved Gas Analysis by Mass Spectrometry (EGA-MS)

The Mettler Toledo TGA/DSC 3+ system offers simultaneous thermal analysis and gas evolution studies, capable of reaching temperatures up to 1500°C. It features an exceptional balance performance with a measuring range of 5 g and an outstanding resolution of 0.1 micrograms, ensuring highly precise measurements. This advanced instrument integrates Thermogravimetric Analysis (TGA) with Differential Scanning Calorimetry (DSC), along with mass spectrometry, enabling the monitoring of material decomposition, phase transitions, and the release of volatile compounds. This system is crucial for both volcanic research and industrial material characterization, providing detailed insights into the thermal behavior and stability of diverse materials.

- Thermal Analysis System TMA/SDTA 2+Our Thermomechanical Analyzer (TMA/SDTA 2+) from Mettler Toledo is a cutting-edge system that offers unparalleled precision in measuring dimensional changes under thermal stress. The system allows for the detection of significant small dimensional variations, with a length resolution as fine as 0.5 nm. With a wide temperature range up to 1,600°C, the TMA/SDTA 2+ is ideal for studying the thermal properties of a diverse range of materials, from volcanic melts to industrial ceramics, making it an indispensable tool for both basic and applied research.The SDTA technology integrated into the TMA/SDTA 2+ offers unmatched temperature accuracy by measuring the sample temperature very close to the sample itself, ensuring reliable and consistent data collection in all operating modes. The system’s SDTA resolution of 0.005°C ensures that even the smallest temperature changes are captured, making it highly sensitive to subtle thermal events. With a measurement range of -5 mm to 5 mm and the ability to accommodate samples up to 20 mm in length, the TMA/SDTA 2+ is versatile enough to handle various research applications.

This system is not only designed for fundamental research but also for industrial applications, offering critical insights into thermal expansion and contraction, phase transitions, and thermal stability of materials. The TMA/SDTA 2+ represents a powerful blend of precision, reliability, and ease of use, making it an essential tool for advancing our understanding of material behavior and pushing the boundaries of innovation in both scientific and industrial fields.

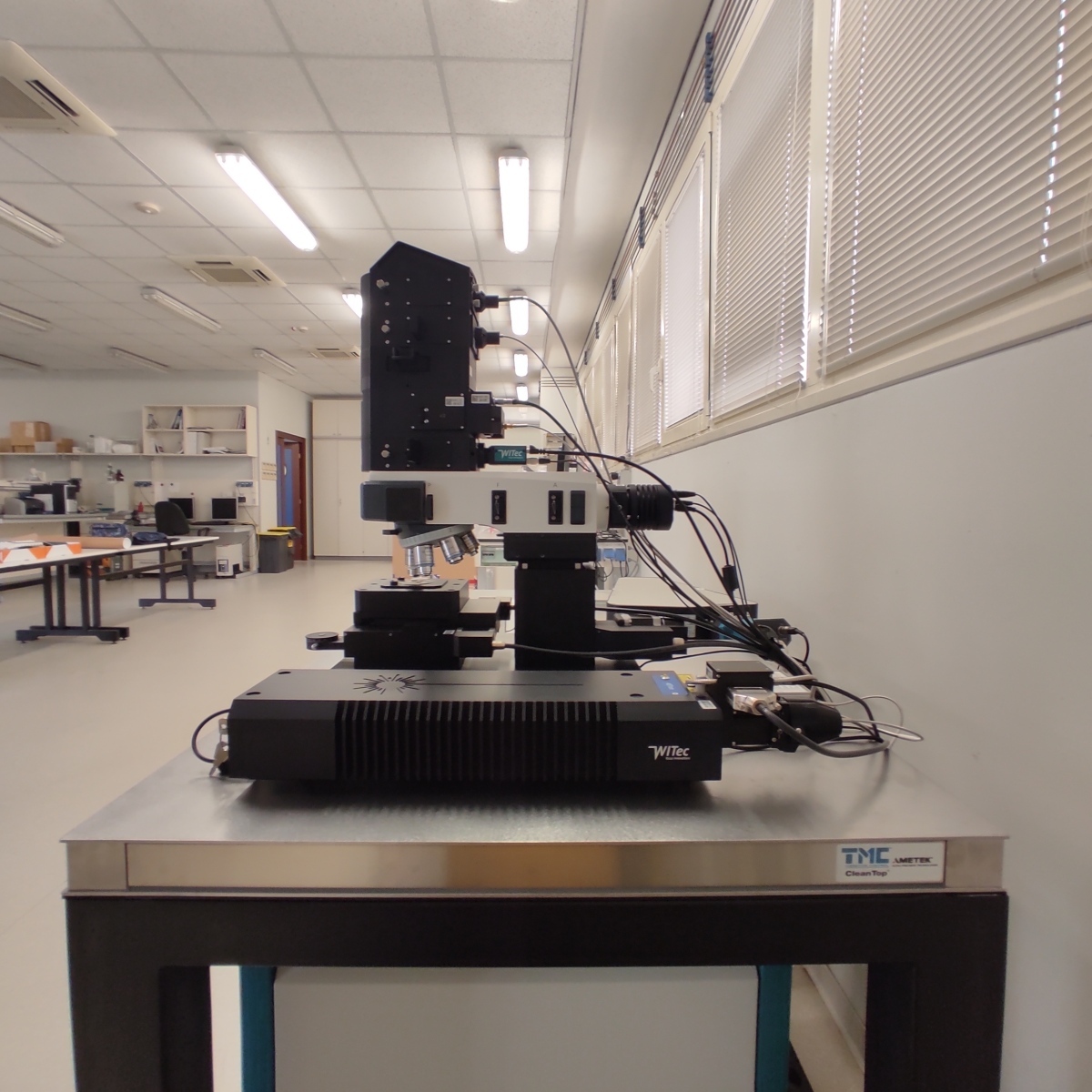

- Raman microscope

Our state-of-the-art Raman microscope provides high-resolution insights into the structure of volcanic materials and industrial samples at the nanoscale. This tool allows us to analyze nanocrystals and molecular structures, offering detailed data on material composition, phase changes, and structural evolution.

- Flash Scanning Differential Calorimeter (FDSC)

Capable of reaching ultra-high heating and cooling rates (up to 3 million K/min), the FDSC from Mettler Toledo is essential for studying fast transitions and reorganization processes in materials. It supports research into volcanic glass formation and industrial applications, including the precise control of glass and ceramic properties across a wide temperature range (-95 to 1,000 °C).

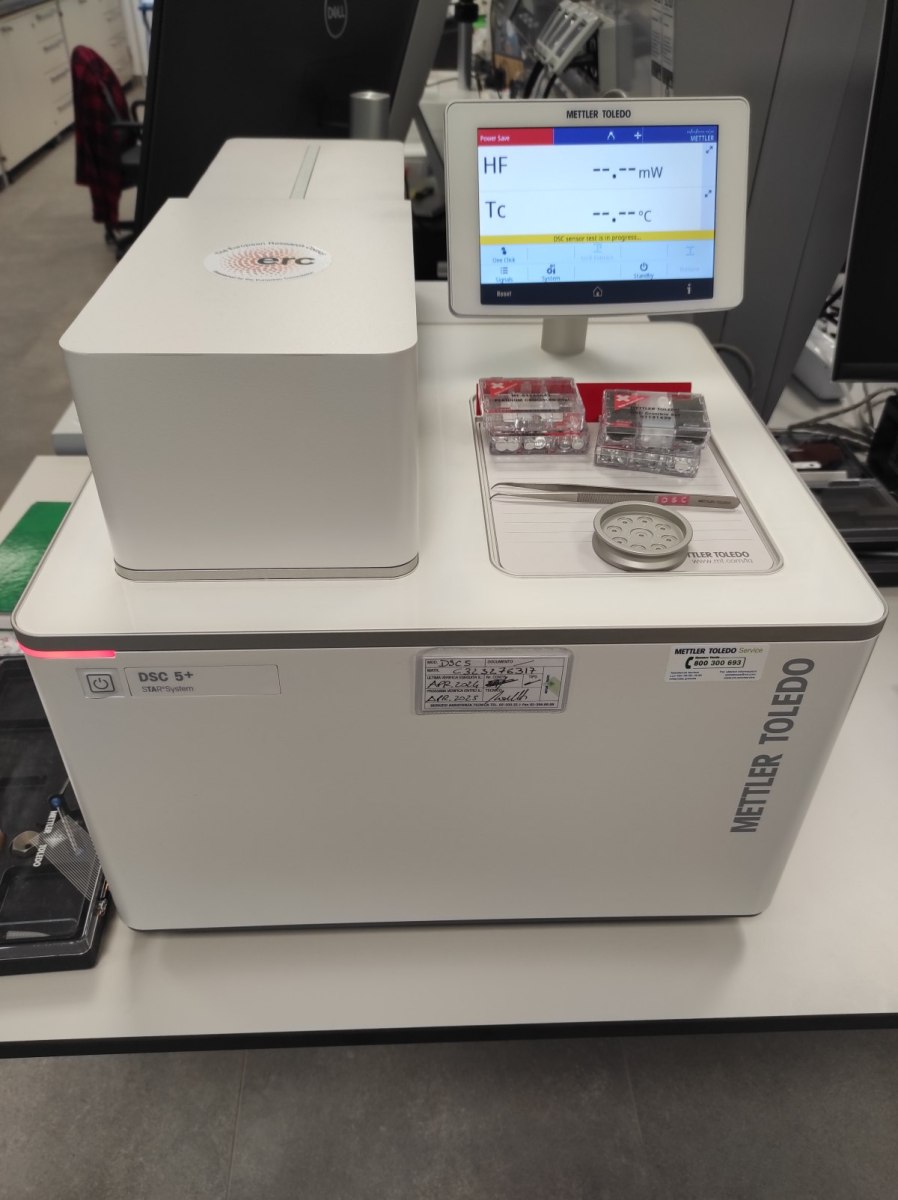

- Differential Scanning Calorimeter (DSC5+)

We are proud to introduce the DSC 5+ from Mettler Toledo, a high-precision Differential Scanning Calorimeter designed to measure the heat flow associated with material transitions. This instrument offers a wide temperature range up to 700°C, allowing us to study thermal properties across a diverse array of materials, including volcanic melts, glasses, ceramics, and polymers. The DSC 5+ provides unparalleled sensitivity and accuracy, making it ideal for investigating phase transitions, melting behavior, glass transition temperatures, and crystallization processes. Its high resolution allows for precise thermal profiling, which is critical for both basic research into volcanic processes and the development of high-performance materials for industrial applications. The DSC 5+ also supports controlled cooling and heating rates, ensuring that even the most subtle thermal events are captured, which is essential for understanding the physicochemical changes in materials under varying environmental conditions. This tool plays a key role in our research into thermal stability, decomposition, and the calorimetric characterization of new materials.

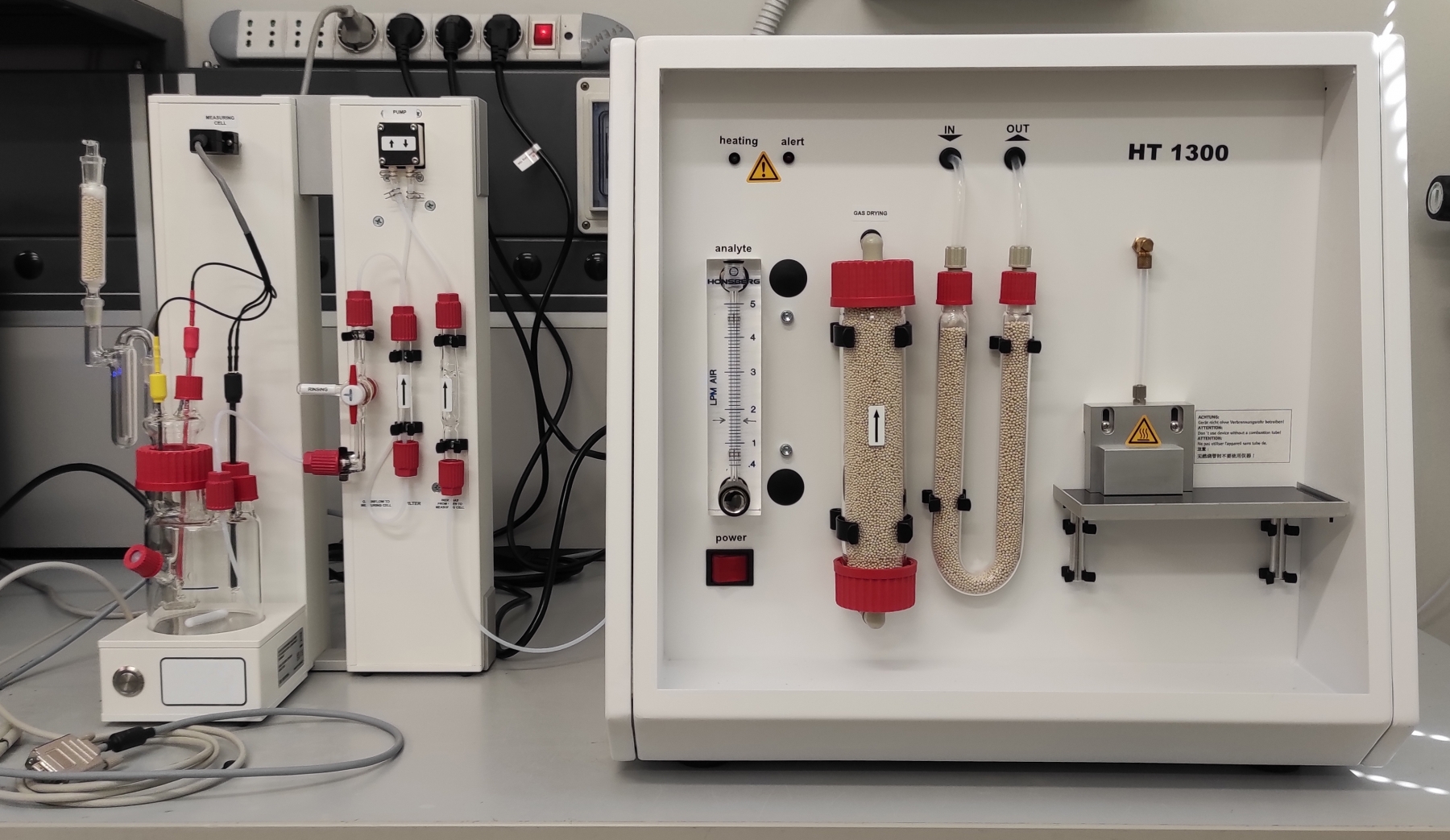

- High-temperature furnace for water extraction and precise quantification

This furnace, coupled with a high-precision Karl Fischer module, allows for the extraction and quantification of water in volcanic and industrial samples. It is indispensable for studying water content in magmas and glasses, which plays a crucial role in both eruption dynamics and material properties in industrial production.

Why collaborate with GLASS?

The GLASS Laboratory provides a unique blend of basic and applied research that offers value to both the scientific community and industry. By partnering with GLASS, companies and institutions can benefit from:

- Insights into volcanic and industrial melts: Our research into high-temperature processes informs both natural and industrial applications.

- High-performance material development: We optimize material compositions for enhanced durability, strength, and thermal resistance, essential for industries working with specialty glasses and ceramics.

- Sustainability and eco-friendly innovation: We lead efforts to reduce environmental impacts by reusing natural and industrial materials, aligning with the circular economy.

- Precision tools and advanced analytics: Our state-of-the-art equipment provides comprehensive data on material behavior, helping industries refine manufacturing processes and innovate new products.

- Understanding of extreme conditions: With our ability to replicate volcanic and industrial conditions, we help develop materials that excel in demanding environments.

Partner with us

Whether you are an academic institution aiming to deepen the understanding of volcanic processes or an industrial leader seeking innovation in material science, the GLASS Laboratory offers a unique platform for collaboration. Our combined expertise in basic and applied research ensures that we deliver both scientific breakthroughs and tangible industrial solutions.

The GLASS Laboratory is where fundamental discoveries in volcanology meet industrial innovation, driving the future of material science for both academia and industry.